-

CLIENT

Abroad

-

DATE

April 16th ,2025

-

PROJECT TYPE

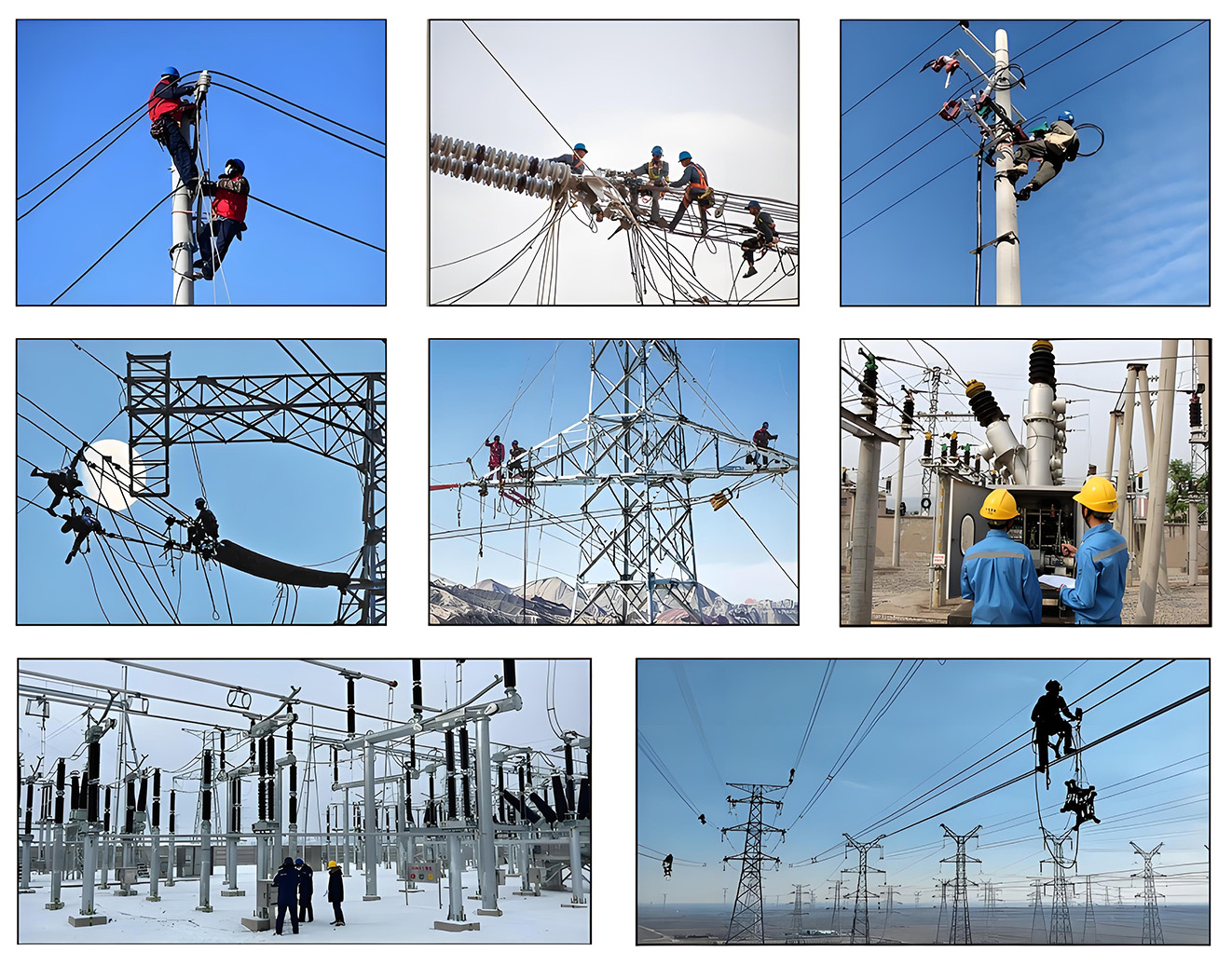

power transmission

power transmission and transformation

The national grid upgrade project aims to build a high-reliability transmission network, integrate renewable energy generation and improve cross-regional power transmission capabilities. The project covers the construction of high-voltage transmission lines and the transformation of intelligent substations, and needs to adapt to complex geographical environments and diverse power grid standards.

Project scale and technical solution

1. High-voltage power transmission project

(1) Transmission type: 500kV AC (HVAC) and ±800kV DC (HVDC) hybrid system.

(2) Line design:

Cross-mountainous lines: Use high towers (tower height 80-120 meters) and helicopters to deploy guide ropes to reduce vegetation damage.

Coastal lines: Composite crossarm anti-salt spray design, insulator creepage distance ≥31mm/kV.

(3) Key equipment:

DC converter valve: IGBT-based modular multilevel converter (MMC), loss ≤ 0.8%.

Smart conductor: Carbon fiber composite core conductor (ACCC), current carrying capacity increased by 30%, sag reduced by 20%.

2. Intelligent substation transformation

(1) Main device upgrade:

750kV GIS: Integrated intelligent monitoring unit (partial discharge, SF6 gas density online monitoring).

Transformer: On-load voltage regulation (OLTC) intelligent transformer, supporting bidirectional power flow (adapting to the reverse transmission of new energy).

(2) Digital system:

Digital Twin Platform: Real-time simulation of power grid faults (such as short circuits, harmonic oscillations) and preview of protection strategies.

Inspection Robot: Indoor track-type robot (infrared temperature measurement + ultrasonic partial discharge detection), replacing 90% of manual inspections.

Core Challenges and Solutions

| Challenge | Innovative Solutions |

|---|---|

| Construction on complex terrain | UAV 3D mapping + BIM modeling optimizes the path and reduces earthwork by 40%. |

| New energy grid-connected fluctuations | Synchronous condenser (300Mvar) is configured to provide inertia support, and the frequency response time is ≤50ms. |

| Multi-standard equipment compatibility | Flexible interconnection transformer (FIT) realizes seamless connection of different voltage levels (220kV/500kV). |

| Extreme climate resistance | Spray anti-icing paint (RTV-II) on outdoor equipment of substations, and add ice melting devices (DC short-circuit current ice melting) on transmission lines. |

Implementation results and value

1. Power transmission efficiency improvement:

The HVDC line has a transmission capacity of 8000MW and a loss of ≤3.5% (the traditional AC solution is about 7%).

The reliability of cross-regional power transmission reaches 99.99%, and the annual power outage time is <5 minutes.

2. Environmental and economic benefits:

Annually deliver 18 billion kWh of clean energy, replace 5.4 million tons of standard coal, and reduce CO₂ emissions by 14.5 million tons.

Modular substation construction shortens construction period by 40% and reduces life cycle cost by 25%.

3. Social benefits:

The proportion of local procurement (tower materials, cable accessories) exceeds 50%, creating more than 1,200 jobs.

Train 200 local operation and maintenance teams to achieve technology transfer and knowledge sharing.

Core service capabilities

1. Full chain technology coverage:

Design end: electromagnetic transient simulation (PSCAD/EMTDC), lightning intrusion wave analysis (ATP-EMTP).

Construction end: tension wire laying technology (to prevent wire wear), high-precision laser calibration (GIS installation error ≤1mm).

Operation and maintenance side: Wide area measurement system (WAMS) + blockchain technology to achieve fault tracing.

2. Compliance with international standards:

Meets IEC 62271 (high voltage switchgear), IEEE C37.234 (protection system) and other standards.

Passed the World Bank ESF (Environmental and Social Framework) assessment and completed the biodiversity compensation plan.

3. Localization support:

Regional spare parts center (48-hour emergency response), multi-language operation and maintenance manual and training system.

Adapt to local power grid dispatching protocols (such as IEC 60870-5-104, DNP3.0).

Technology Innovation and Future Expansion

Superconducting cable pilot: -196℃ liquid nitrogen cooling superconducting power transmission (loss close to zero), reserved interface compatible with future upgrades.

Hydrogen energy coupling: Electrolyzers are integrated in the substation to produce hydrogen using surplus electricity (efficiency ≥ 75%).

AI predictive maintenance: Machine learning analyzes equipment aging trends, and the accuracy of spare parts replacement prediction is ≥ 90%.